Main section description:

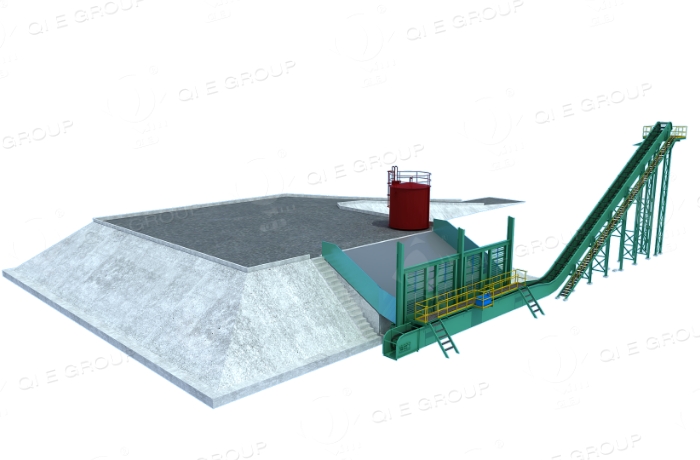

Raw material reception station: as palm fruit unloading, cleaning, storage platforms, all hydraulic segmented discharge.

Sterilizing station: The purpose is to break the enzymes in fruit, and to avoid the increasing of the FFA content in oil. At the same time, the high temperature makes fruit soft.

Threshing station: The purpose is to separate the palm fruit from the FFB. The separated palm fruits are sent to the digesting & pressing section. Empty palm fruit bunches are transported to boiler room as fuel.

Digesting & Pressing station:

Digesting is for breaking off the palm fruit, and with high temperature to soften the fruit and kills the bacteria. Pressing is to use double-screw palm oil press to extract palm oil. Crude palm oil can be got at this station.

Clarification station: The purpose is to remove some fiber, mud or other impurities. After clarification, the purified palm oil can be directly sold or deeply refining.

Palm Kernel recovery: After pressing, the palm kernel and fiber mixture can be processed by further separation. After drying, the palm kernels are stored for deep processing, and the separated fiber and shells are used as the boiler fuel for providing steam.